In electrical design, selecting the appropriate conduit size ensures safety, compliance, and operational efficiency. Overcrowded conduits may cause overheating, increased voltage drop, and fire risks.

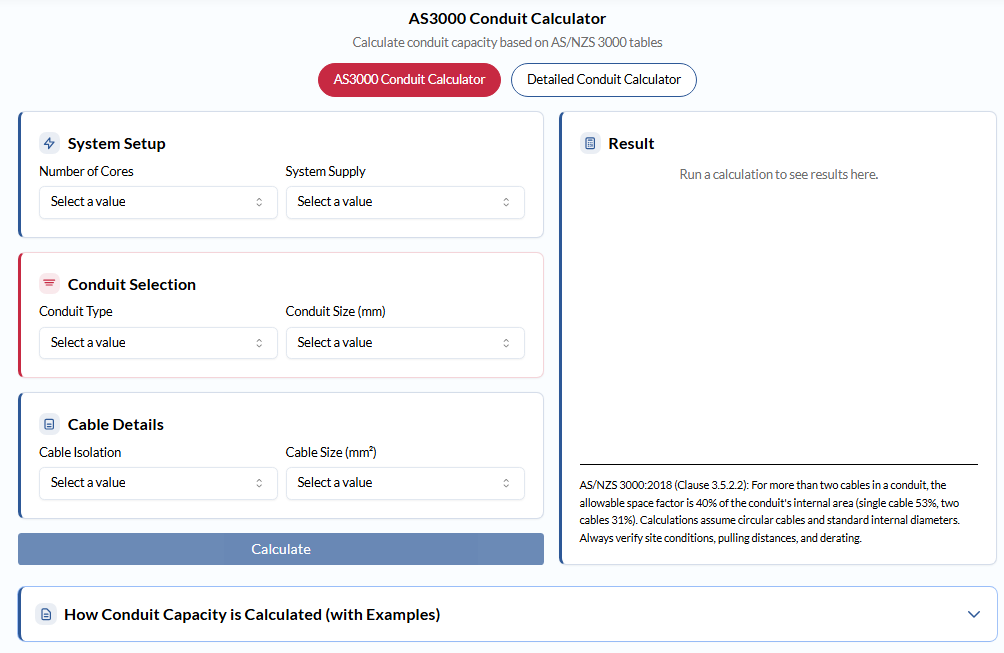

CableHero’s Conduit Calculator provides a faster process to determine the correct conduit size, following the Australian Standards AS/NZS 3000 and AS/NZS 3008. This guide offers a detailed walkthrough of the tool’s features and operational steps.

Note: CableHero‘s Conduit Calculator is based on the preterm values in AS3000’s Tables C10, C100, and C12.

CableHero Calculation Guide

This guide will help you make data-driven decisions with confidence during conduit planning. Automating complex sizing logic reduces the likelihood of manual errors and ensures accurate installation.

Create New Project

After logging into CableHero, create or add a new project by clicking the folder icon.

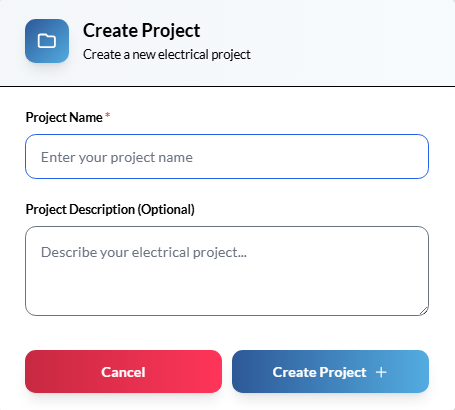

Once the Create Project tab appears, input your Project Name and Project Description (Optional).

Add a New Calculation

To start a new calculation, click the New Calculation button.

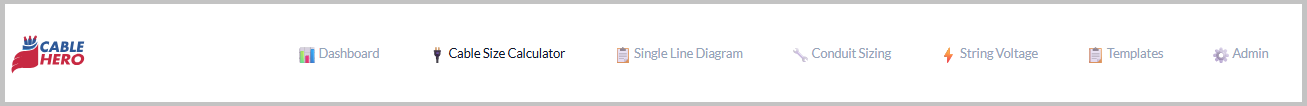

It will then automatically redirect you to CableHero’s cable sizing calculator. To access the conduit calculator, click Conduit Calculator on the top navigation bar.

How to Use CableHero Conduit Calculator

The tool requires several inputs to perform accurate conduit sizing calculations. Each input plays a specific role in determining the appropriate conduit size.

Number of Cores

This parameter defines the number of conductive cores present within each cable, such as single-core or multi-core options. A single-core cable contains one conductor, while a multi-core cable contains two or more insulated conductors within a single sheath. The number of cores affects the cable diameter and influences heat dissipation within the conduit.

In the calculator, select the appropriate number of cores from the drop-down menu:

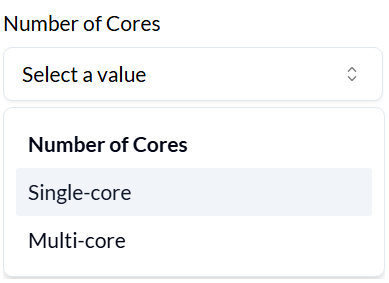

System Supply

System supply refers to the electrical configuration of the circuit, typically single-phase, three-phase, or direct current. Single-phase (1ph) systems use two conductors, three-phase (3ph) systems use three or four, and direct current (DC) provides constant voltage using positive and negative terminals. These affect the current rating and installation method used for the calculation.

Choose the relevant system supply from the drop-down menu:

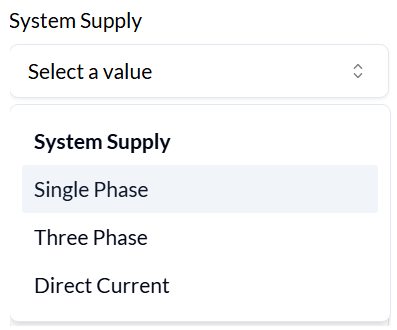

Conduit Type

This input identifies the conduit material and structure, such as heavy-duty rigid UPVC, Corflo, or medium-duty corrugated conduit.

- Heavy-duty rigid UPVC – offers high mechanical strength for outdoor or underground use,

- Corflo – provides flexibility for confined spaces

- Medium-duty corrugated – lightweight for indoor use

- Medium rigid UPVC – offers a balance of strength and ease of installation in general applications

The selected type affects mechanical protection, internal diameter, and conduit fill capacity.

Select the desired conduit type from the drop-down menu:

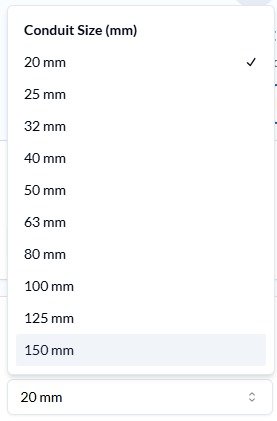

Conduit Size

Conduit size specifies the nominal diameter of the conduit used for cable routing. The size determines the internal space available for cables and impacts compliance with fill capacity requirements.

Choose the conduit size from the drop-down menu:

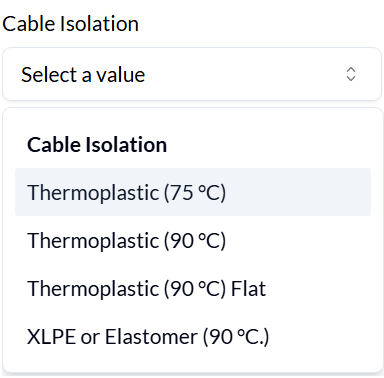

Cable Insulation

This defines the material used to insulate the conductors, such as PVC or XLPE. Different insulation types have varying thermal properties, which influence derating factors and allowable current carrying capacity.

Thermoplastic materials like PVC soften under heat. Meanwhile, cross-linked polyethylene (XLPE) and elastomeric insulations maintain stability at higher temperatures and offer improved thermal endurance.

Select the cable insulation type from the drop-down menu:

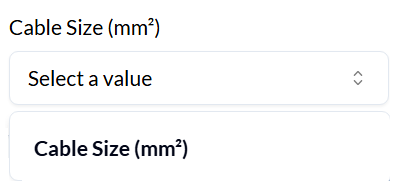

Cable Size

This indicates the conductor cross-sectional area, typically measured in mm². It directly affects current capacity, voltage drop, and the cable’s physical dimensions.

Choose the cable size from the drop-down menu:

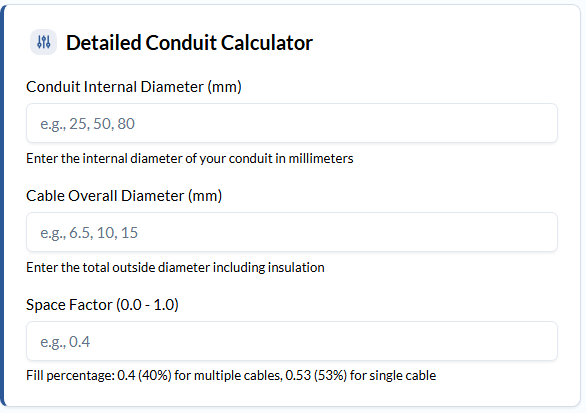

Detailed Conduit Calculator

Detailed conduit calculator provides accurate conduit size pricing so that you know your cable’s overall diameter and its jamming factor.

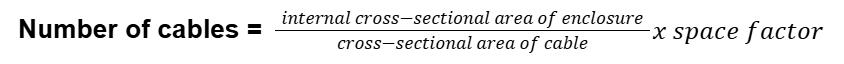

The number of cables that can be installed in a circular conduit is determined by the ratio of the conduit’s internal cross-sectional area to the total cross-sectional area of the cables, which is calculated using the following formula:

Where the space factor recognises the reduction of space available from the circular geometry of the cables and enclosures.

- For one cable in enclosure = 0.5

- For two cables in enclosure = 0.33

- For three or more cables in enclosure = 0.4

Input Parameters

- Conduit Diameter – The internal diameter of the selected conduit is used to determine available space for cable installation.

- Cable Overall Diameter – The total outer diameter of each cable, including insulation and any external sheathing.

- Space Factor – A ratio derived from cable and conduit dimensions used to estimate the likelihood of cable jamming.

All input values can be entered in the designated fields of the calculator interface.

Here’s a quick guide on how to interpret the results:

Jamming Factor Guidelines

- 1.0 to 2.5: Little to no chance of jamming.

- 2.8 to 3.2: High probability of jamming (increase conduit size or reduce the number of cables).

- Above 3.2: Unlikely to experience jamming, but excessive free space may lead to inefficient use of conduit space.

Finalise Your Conduit Plan with Confidence

The CableHero Conduit Sizing Tool facilitates the process of determining an appropriate conduit size while maintaining compliance with AS/NZS 3000 wiring rules. Following the outlined steps and recommendations enables electrical professionals to make informed decisions, supporting safe and efficient installations.

In addition to the conduit calculator, CableHero offers a voltage drop calculator, wire size calculator, and solar cable size calculator to support various aspects of electrical design. Try CableHero today and register for a free trial!

Note: The number of cables determined by the calculation assumes that the enclosure is relatively short, free from obstructions or distortions, and contains minimal bends. In longer runs or more complex pathways, cable quantities should be reduced accordingly to maintain compliance with allowable pulling tensions and minimum bending radius requirements.

Frequently Asked Questions (FAQs)

Explore answers to common questions about conduit sizing and compliance with AS/NZS 3000 standards:

How to calculate conduit size for cables?

To calculate conduit size, determine the total cross-sectional area of the cables and apply the allowable fill percentage based on the number of cables. You can also use a reliable conduit calculator for faster results.

What are the consequences of selecting the wrong conduit size?

Choosing the wrong conduit size can lead to several issues, including difficulty during cable pulling, overheating, physical cable damage, or non-compliance with regulations. It may also reduce the longevity of the installation and increase maintenance costs over time.