As an electrician or engineer, selecting the right cable for your installation goes beyond simply matching the cable to the expected load. You also need to make sure the cable can safely handle fault conditions without damage.

Fortunately, a reliable cable sizing calculator can simplify this process and improve accuracy. It includes fault current, voltage drop, ambient temperature, and installation conditions, so you can choose the right cable size for every project.

What Is Fault Current?

This current is the sudden surge of electricity that flows when a short circuit or earth fault occurs in a circuit. For example, if an active conductor accidentally contacts the neutral cable or earth, the current spikes dramatically.

It’s worth noting that this surge can be significantly higher than the normal operating current, even though it usually lasts only milliseconds. Despite its brief duration, fault current produces intense heat and mechanical forces that can damage cables, appliances, and equipment if not properly managed.

That’s why you need to know how much fault current your cables might handle. This depends on factors like the transformer size, cable type, and circuit design.

Why Fault Current Matters for Cable Sizing

When fault current flows through a cable, it creates intense heat and mechanical stress. Even if the circuit breaker or fuse trips quickly, the cable still needs to handle that short burst of energy without melting, deforming, or catching fire.

So if you choose a cable that can’t handle fault current, you increase the risk of failure when a fault happens. This can put people at risk, cause downtime, and lead to expensive repairs. That’s why knowing how to size cables properly is important. Aside from looking at the normal running load, your sizing also needs to ensure the cable can safely survive fault conditions.

Factors to Consider When Sizing Cables

Several technical factors influence your cable sizing choices, including:

- Current-Carrying Capacity: Make sure the cable can handle the expected continuous current without overheating. This depends on the conductor material, insulation type, and installation environment.

- Voltage Drop: Keep the voltage drop under 5% to avoid equipment issues and wasted energy. The longer the cable, the more voltage drop you’ll get, which may mean choosing a larger cable size.

- Ambient Temperature: High temperatures reduce how much current a cable can carry. So, use correction factors if the cable is in a hot area or an enclosed space.

- Installation Method: Whether the cable runs underground, in conduit, or bundles affects heat dissipation. Remember to apply derating factors based on how the cable is installed.

- Conductor Material: Copper cables have better conductivity but are more expensive. Meanwhile, aluminium is often used for longer runs or when budget concerns are high.

- Supply System: Cable sizing differs between single-phase and three-phase systems, so make sure you use the correct method.

- Prospective Fault Current: The fault current that is expected to pass into the cable under fault conditions.

To size cables accurately, always refer to AS/NZS 3008.1 and use a trusted cable sizing calculator. This will help you apply the standards correctly while saving time and reducing the risk of errors.

How Cable Length Affects Your Cable Choice

Cable length directly affects voltage drop and fault loop impedance. Longer cables have higher resistance, which increases voltage drop and reduces fault current. Meanwhile, a lower fault current may delay the protective device’s tripping, letting the cable heat up more than safe limits during a sustained fault. So, it’s best that you select a larger cable to ensure safety during fault conditions.

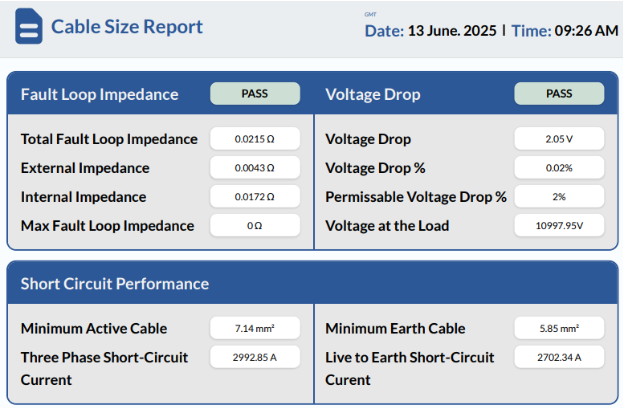

For long runs, you should calculate voltage drop and loop impedance carefully. With CableHero’s voltage drop and fault impedance calculators, it can help verify whether your design meets performance and safety standards.

How to Calculate Fault Current

Estimating fault current helps verify that your cable and protective devices are compatible. To calculate fault current, consider:

- Transformer kVA and impedance

- Cable length, size, and resistance

- System voltage

- Total fault loop impedance

The basic formula for fault current is:

In this way, it gives you the prospective short-circuit current at a specific point in the circuit. To estimate fault loop impedance, you need to account for the impedance of the transformer, cables, and connections back to the source.

How CableHero Calculates Minimum Cable Size for Fault Current

After estimating the fault current, it’s important to ensure that your selected cable can safely withstand the thermal stress caused by a short circuit. According to AS/NZS 3008.1.1:2017, the minimum conductor size required to survive a fault is calculated using this standard formula:

Where:

- S = minimum cross-sectional area (mm²)

- I𝓀 = fault current (A)

- t = fault duration (s)

- 𝓀 = material constant (e.g., 115 for copper/PVC)

Standard Note: AS/NZS 3000:2018 allows using 80% of the nominal transformer or network impedance when actual fault current values are unknown (Clause 2.5.3.2.1 Note 2).

With CableHero, you don’t need to worry about calculating this manually. Our cable sizing calculator automatically factors in short-circuit withstand based on AS/NZS 3008.1.1. It ensures your cable meets both thermal and safety requirements, so you can confidently select the right cable every time.

Note: As per AS/NZS 3000:2018, Clause 2.5.3.2.1, Note 2:

“For low-voltage consumers’ mains, where the prospective short-circuit current is not known, a value of 80% of the nominal transformer or supply authority impedance may be used for calculations

Choose the Right Cable Every Time with CableHero

Your responsibility as an electrician includes making sure cables perform safely and efficiently under all conditions. By understanding fault current and how it affects cable sizing, it helps you design safer, more dependable installations.

Fortunately, CableHero’s cable sizing calculator makes this process more accurate and efficient. By carefully calculating cable sizes and using the right tools, you reduce risk, avoid costly errors, and ensure your work meets Australian standards. Get in touch with us today to learn more about our innovative tools!

Frequently Asked Questions (FAQs)

Here are other details on what you need to know about using a cable sizing calculator for safe and accurate installations:

How to calculate cable sizing?

To calculate cable sizing, determine the load current, allowable voltage drop, installation conditions, and short-circuit capacity. Use AS/NZS 3008.1.1 tables or a cable sizing calculator for accurate results.

How often should I recalculate cable sizes for an existing installation?

Recalculation is recommended when load, protective devices, cable route, ambient conditions, or system configuration changes. It helps ensure ongoing compliance and safety.

Why is voltage drop important in cable selection?

Too much voltage drop can cause equipment to malfunction or reduce energy efficiency, especially over long distances. Keeping voltage drop within recommended limits helps maintain consistent performance and ensures compliance with standards.