One of the most overlooked yet important factors when designing an electrical system is the way cable sizing affects grouped cables and conduits. Grouping multiple cables or running them through a single conduit increases heat buildup, which reduces current-carrying capacity and compromises system performance.

That’s why sizing accurate cable length is important, as it ensures these wires don’t lead to overheating, premature insulation failure, or fire hazards. With that said, this article explains how cable sizing is affected by grouped cables, conduits, and other installation factors.

Factors That Impact Cable Sizing in Groups

When multiple cables are installed close together, they don’t dissipate heat as effectively as a single cable. This can affect their current-carrying capacity, which is why grouped cables and conduits require careful consideration in terms of cable size and installation length. Here are the main factors that influence this:

Heat Accumulation in Bundled Cables

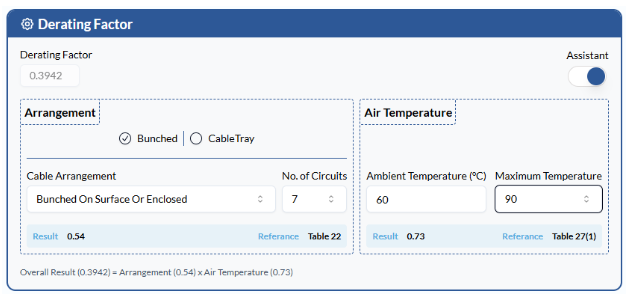

Grouped cables restrict airflow and trap heat, reducing their ability to safely carry current. This phenomenon, known as thermal derating, is an important factor in determining how to size cables properly. Derating cables is necessary because bundles of wires increase the temperature around each cable, making it harder for the overall heat to dissipate efficiently. This means the cable’s ability to carry current without overheating drops.

For instance, if a cable is rated to carry 40 amps under ideal conditions, that same cable in a group of six inside a conduit may only be safe at 26–28 amps. If the load remains the same, but the cable isn’t lengthened or upsized to compensate for derating, it can overheat, trip breakers, or even degrade insulation over time.

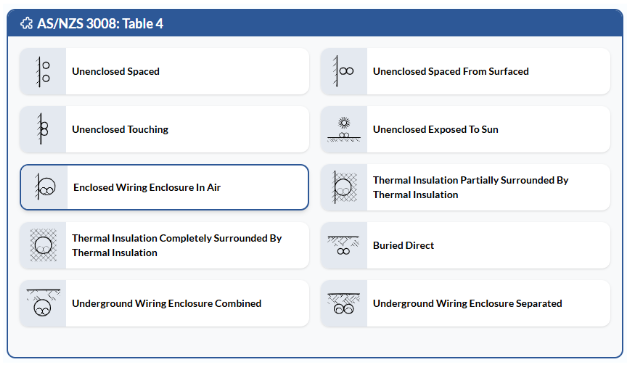

The primary Australian electrical standards, AS/NZS 3008.1.1:2017 and AS/NZS 3000:2018, require the use of derating factors when multiple cables are grouped together. These account for the number of cables, type of enclosure, and installation environment, as heat buildup reduces the cables’ current-carrying capacity.

In addition, applying these adjustments manually requires expertise, attention to detail, and time. Unfortunately, it is common to rush this process, especially on complex projects that involve many grouped runs, which can lead to undersized cables and underperforming potential.

Sizing Conduits for Grouped Cables

Grouping cables or cords can also affect the size of conduits. When multiple cables are installed in a single conduit or tube, they occupy space and generate heat. A conduit that’s too small can put mechanical stress on the cables, which complicates installation and traps excess heat due to poor ventilation.

According to AS/NZS 3000:2018, Clause 3.9.3.2 and Appendix C, conduits must not exceed the allowable space factor, which typically limits cable fill to no more than 40% of the conduit’s internal cross-sectional area.

The fill percentage is calculated using this formula:

Where

- Ac = cross-sectional area of each individual cable

- Ad = internal cross-sectional area of the conduit

- The total must not exceed 40% for general installations

This equation ensures adequate heat dissipation, reduces pulling resistance, and helps prevent long-term cable damage. In practice, calculating the correct conduit size for multiple cables, especially for different types and diameters, can be a tedious process without the right tools.

Fortunately, a reliable cable and conduit calculator can address this challenge by integrating fill ratios, space factor compliance, and heat dissipation into its sizing logic. When you input your system layout, it recommends both the correct cable size and suitable conduit based on grouping and installation method. For this reason, the safety and compliance are ensured to be within Australian standards.

The Challenge of Calculating Cable Size

Manually calculating how to size cables for grouped configurations involves more than just looking up tables as references. Experienced electricians also struggle when they need to factor in all variables, such as:

- Cable length (to account for voltage drop)

- Installation method (conduit, free-air, buried)

- Grouping factors and derating

- Ambient temperature

- Conductor material (copper or aluminium)

- Load type (continuous or variable)

- Conduit size

Each of these factors influences the final cable size. In the worst-case scenario, the material costs unnecessarily increase if you oversized to be “safe.” On the other hand, undersizing increases the risk of tripping circuits and overheating.

Ultimately, cable selection calculators are available to streamline this complicated process. These tools allow electricians and engineers to input parameters such as cable length, number of cables, and conduit type to get the appropriate cable size with all derating factors applied. Not only does this make planning faster and more accurate, but it also improves the safety and compliance of the final installation.

Get Sizing Done Right with Cable Hero

Grouped cables and shared conduits add complexity to electrical installations that can’t be ignored. Heat buildup, derating, and conduit space limitations are factors that make proper cable sizing a crucial step, especially when energy demands increase across commercial and industrial applications.

Cable length, combined with grouping and conduit conditions, are vital in finding whether a wire can be a hazard or do its job. With smart tools like CableHero’s cable sizing calculator, you can take the guesswork out in cable selection. By accounting for actual conditions, professionals can design safer, more reliable electrical installations with ease. For more information, sign up for a free account today!

Frequently Asked Questions (FAQs)

Conduit sizing and derating are important aspects to consider when designing safe and efficient electrical installations due to environmental and load conditions. Here are some related questions:

What are the factors to be considered when deciding the size of conduit for electrical wire?

Conduit size depends on the number of conductors, their insulation type, and their total cross-section area. When deciding the size, you should consider the ease of pulling cables, future expansion, and heat dissipation requirements.

What is the group derating factor?

The group derating factor is a reduction applied to the maximum current-carrying capacity of cables installed in proximity. It accounts for reduced heat dissipation when multiple cables are grouped, ensuring a safe thermal performance.