A cable tray is a support system used in buildings for electrical wiring. It provides support for insulated cables, primarily used for power distribution. Cable trays are a popular choice for cable management in commercial and industrial buildings, offering an alternative to electrical conduit or open wiring systems. They play a crucial role in the design and are essential when modifications to the wiring system are needed.

There are different types of cable trays that cater to specific needs. Let’s explore some of them.

Types of Cable Trays

1. Trough Cable Tray

These moderately ventilated trays provide cable support and come in metallic and non-metallic variants. They are suitable for moderate heat-generating activities with support spans ranging from 0.3 to 6 meters.

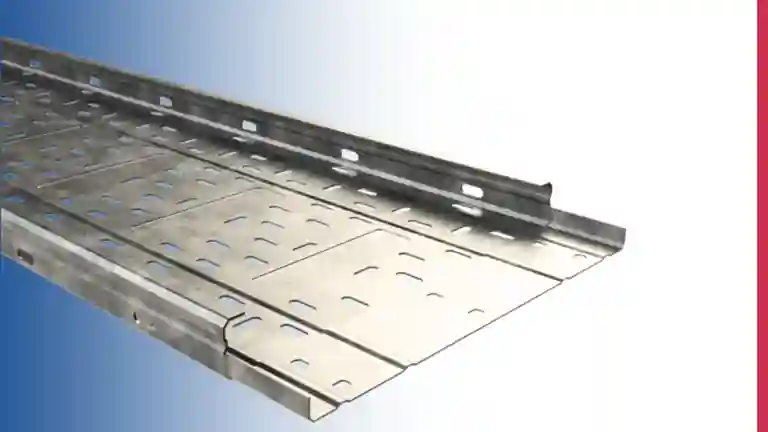

2. Perforated Cable Tray

Featuring a ventilated bottom and side rails, this tray offers strong cable support compared to ladder cable trays.

3. Ladder Cable Tray

This type features two side rails connected by rungs. It offers easy accessibility to cables and provides a secure anchor for tying down cables, especially in non-horizontal tray runs.

4. Channel Cable Tray

Used in installations with a limited number of trays, these trays are designed for situations where cables exit through ventilation openings and may experience vibration. They come in standard widths and lengths.

5. Wire Mesh Cable Tray

Also known as a basket cable tray, this type is made by welding stainless steel wires together to form a mesh. It is commonly used for telecommunication, low voltage, and fiber optic cables.

6. Single Rail Cable Tray

These trays can have single or multiple trays and can be wall-fixed or centrally supported. They are flexible for power distribution and commonly used for low power cables.

7. Solid-Bottom Cable Tray

This tray is preferred when cable drooping may affect system performance. It is also suitable for situations where electromagnetic interference protection is crucial.

Materials Used To Make Cable Trays

Cable trays can also be categorized based on the material used:

• Metallic Cable Trays

Made of aluminum, steel, or stainless steel, these trays are known for their corrosion resistance, strength-to-weight ratio, and suitability for various environments.

• Non-Metallic Cable Trays

Typically made of fiberglass, these trays are non-conductive, corrosion-resistant, and lightweight. Proper bend radius maintenance is crucial for coaxial or fiber-optic cables.

Cable trays act as bridges, allowing safe transportation of wires and protecting them from overheating. Understanding the different types of cable trays helps in selecting the most suitable option for specific project requirements.

Cable Sizing for Cable Trays

And for specific cable sizing needs, CableHero web and mobile cable sizing calculator can do the job for you. Register for a free trial today.

Disclaimer: Although CableHero provides important and accurate tips and information through this website, CableHero does not make any representations or warranties as to the completeness, precision, trustworthiness, or timeliness of such information, and CableHero does not claim any duty to be held liable from the usage of the information.